The Future of Manufacturing: **3D Printing Rapid Prototyping Services**

In today's fast-paced business environment, rapid prototyping has become a cornerstone of innovation and product development. Organizations are increasingly adopting advanced technologies to streamline their processes, reduce costs, and accelerate time-to-market. One such transformative technology is 3D printing, which is revolutionizing the way prototypes are created across various industries. This article delves into the myriad advantages of 3D printing rapid prototyping services, with a specific focus on how DeepMould.net is leading the charge in this domain.

What is 3D Printing Rapid Prototyping?

3D printing is an additive manufacturing technique that allows businesses to create three-dimensional objects from digital files. This technology utilizes various materials to produce intricate designs and prototypes quickly and efficiently. Rapid prototyping refers to the speed at which these prototypes are developed, enabling businesses to iterate on their designs faster than traditional methods. With 3D printing rapid prototyping services, companies can bring their ideas to life in a matter of days rather than weeks or months.

Key Advantages of 3D Printing Rapid Prototyping Services

By leveraging 3D printing technologies, businesses can unlock a plethora of benefits:

- Speed: Traditional prototyping methods often involve lengthy processes. With 3D printing, prototypes can be fabricated in a fraction of the time, allowing teams to explore ideas rapidly.

- Cost-Effectiveness: Producing prototypes through 3D printing reduces material waste and eliminates the need for expensive tooling, significantly lowering overall costs.

- Design Freedom: 3D printing allows for complex geometries and intricate designs that are often unachievable with conventional manufacturing techniques.

- Material Variety: A wide array of materials can be used in 3D printing, from plastics to metals, accommodating different project requirements.

- Easy Iteration: The ability to quickly make modifications and produce new prototypes fosters innovation and helps businesses stay ahead of competitors.

How DeepMould.net Excels in 3D Printing Rapid Prototyping

As a premier provider of 3D printing rapid prototyping services, DeepMould.net excels in both quality and innovation. Here are some reasons why businesses choose DeepMould for their prototyping needs:

1. Expertise in Metal Fabrication

One of the standout features of DeepMould.net is our specialization in metal fabricators. While many companies focus solely on plastic prototypes, our expertise extends to various metals, making us the go-to source for durable and functional prototypes.

2. State-of-the-Art Technology

DeepMould utilizes the latest 3D printing technologies to ensure accuracy and precision in every prototype. Our investment in cutting-edge equipment means we can take on projects that demand high standards.

3. Tailored Solutions for Every Client

At DeepMould, we understand that each project is unique. Our team collaborates with clients to design customized solutions that meet specific needs, ensuring complete satisfaction and success in achieving project goals.

4. Commitment to Quality Assurance

Quality is our top priority. We implement rigorous quality control measures throughout the 3D printing process, ensuring that every prototype meets industry standards and client expectations.

5. Comprehensive Support Services

From initial design conceptualization to final production, DeepMould provides comprehensive support at every stage of the prototyping process. Our team is always available to answer questions and provide guidance.

Industries Benefiting from 3D Printing Rapid Prototyping

The versatility of 3D printing rapid prototyping services extends across various sectors, enabling businesses to enhance their operations and product offerings:

- Automotive: The automotive industry relies on rapid prototyping to develop components, test design concepts, and reduce lead times.

- Aerospace: Aerospace manufacturers utilize 3D printing for lightweight components, streamlining production while adhering to strict regulations.

- Healthcare: In the healthcare sector, 3D printing rapid prototyping facilitates the development of custom prosthetics, implants, and surgical models, enhancing patient care.

- Consumer Products: Companies in the consumer goods space can quickly prototype new designs, enabling faster market entry and better alignment with customer needs.

- Electronics: The electronics industry employs rapid prototyping to create intricate components and enclosures, driving innovation and efficiency.

The Process of 3D Printing Rapid Prototyping

Understanding the journey from concept to final product is vital. Here’s how the 3D printing rapid prototyping process works at DeepMould.net:

1. Design Initiation

The process begins with a collaborative discussion between our design team and the client. We gather requirements and specifications to create an optimal design plan.

2. Digital Prototyping

Using computer-aided design (CAD) software, our team generates a digital model of the prototype. This stage allows for modifications and adjustments before production begins.

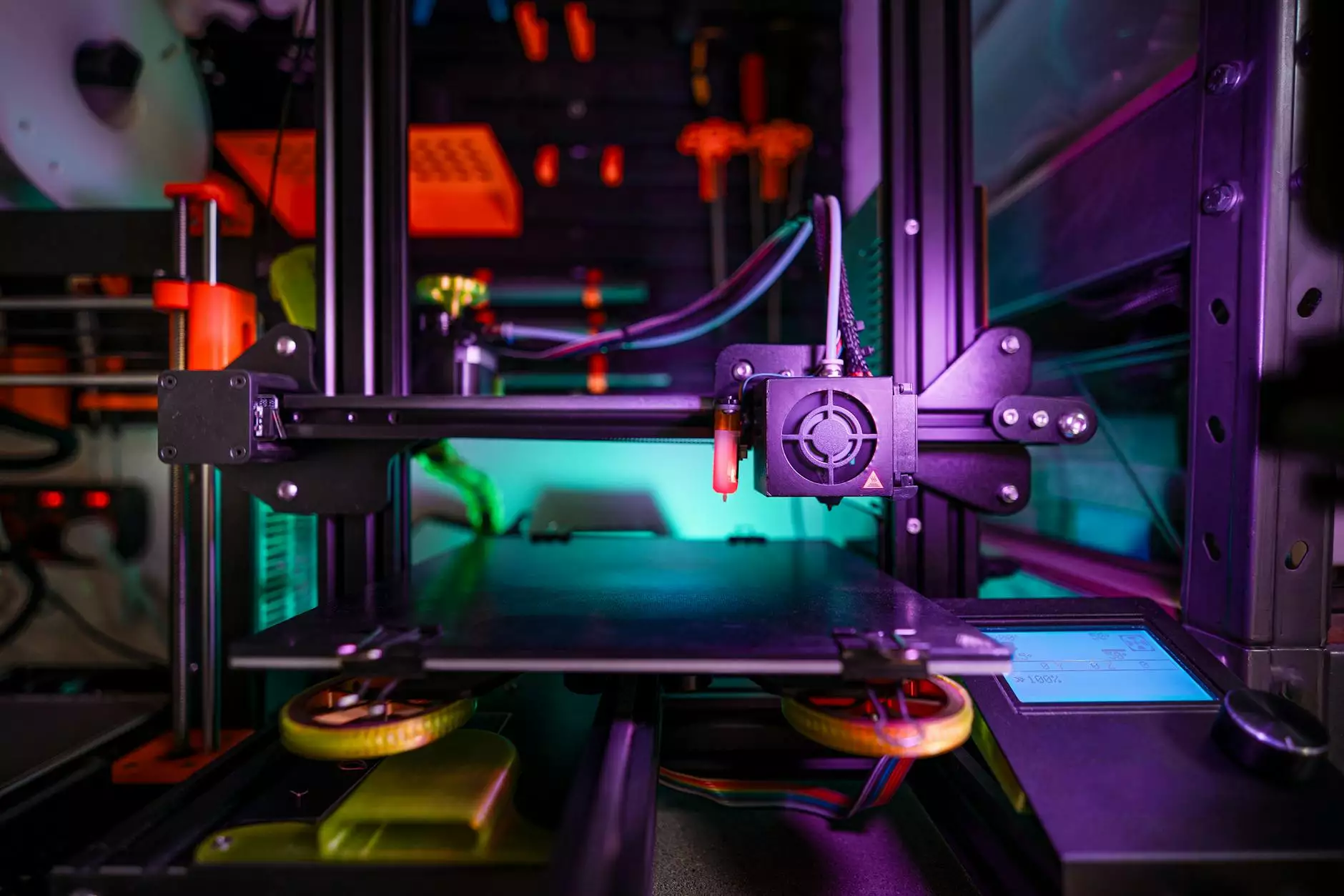

3. 3D Printing Production

Once the design is finalized, we proceed with 3D printing. Our state-of-the-art printers fabricate the prototype layer by layer, utilizing the selected materials.

4. Post-Processing

After printing, prototypes may undergo various post-processing techniques, such as sanding, painting, or assembling, to achieve the desired finish and functionality.

5. Quality Assurance and Delivery

Before delivery, each prototype undergoes rigorous quality checks to ensure it meets our high standards. Following approval, prototypes are delivered to clients for evaluation and testing.

Why Choose DeepMould.net for Your 3D Printing Rapid Prototyping Services?

Choosing the right partner for 3D printing rapid prototyping services can make or break your project. Here are compelling reasons to select DeepMould.net:

- Experienced Team: Our skilled professionals bring years of experience in both 3D printing and metal fabrication, ensuring you receive top-notch service.

- Custom Solutions: We recognize that each client has unique needs, and we craft tailored solutions to cater to your specific requirements.

- Fast Turnaround: We pride ourselves on our ability to deliver high-quality prototypes without unnecessary delays, keeping your projects on schedule.

- Competitive Pricing: Our cost-effective solutions offer maximum value without compromising on quality.

- Positive Client Relationships: We value our clients and strive to build long-term partnerships based on trust, transparency, and mutual success.

Conclusion

As industries continue to evolve, the demand for rapid prototyping solutions will only increase. 3D printing rapid prototyping services emerge as a crucial tool for organizations looking to innovate and improve their product offerings. By partnering with experts like DeepMould.net, businesses can unlock the full potential of this transformative technology and stay ahead in the competitive landscape. Whether you are in automotive, aerospace, healthcare, or any other sector, embracing 3D printing will enhance your design processes, drive efficiency, and pave the way for future advancements.

To learn more about how DeepMould.net can assist you in your prototyping needs, visit our website or contact us today for a consultation.